Blade, Balance, and Why What’s Where

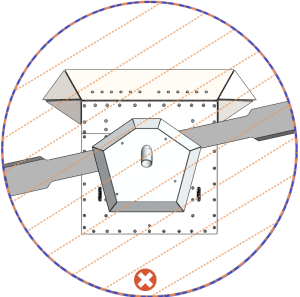

Some people look at Icewave and immediately wonder about the form factor, citing (rightly so) that to be stable, it would be better to have more of a helicopter setup. That is – with the blade atop both the drive train base and the internal combustion engine.

Why does Icewave sandwich the blade between the engine and the base?

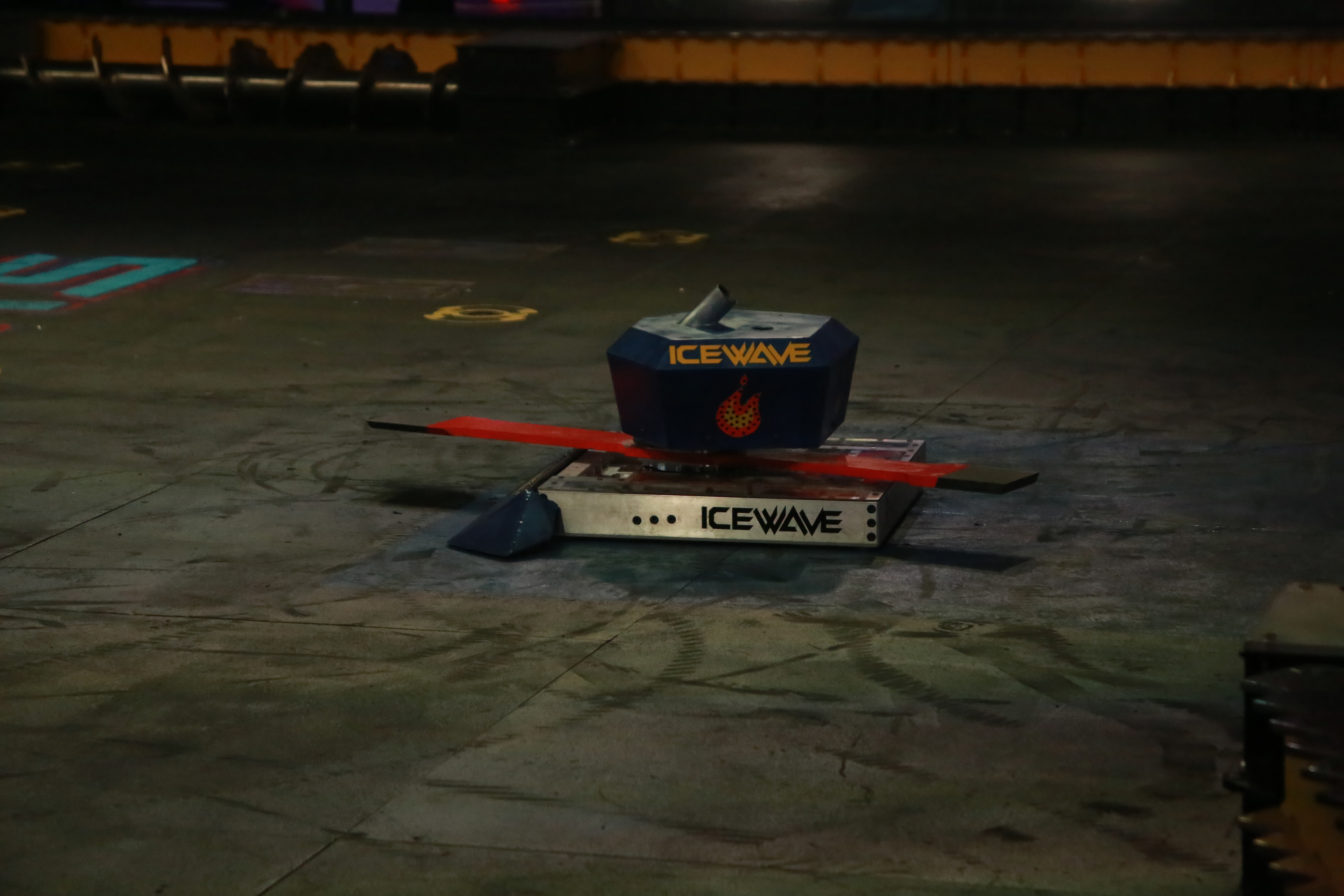

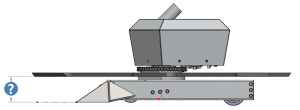

There are a handful of reasons, but the most compelling is simply this: A murderous weapon that cannot reach its target might as well be a fluffy teddy bear spinning around your robot. And the closer you get to the ground, the higher your chances of hitting SOMETHING every time you get near your opponent. Until flying bots make a showing in the arena, that is a golden rule.

Sorry, but our blade height is classified. Trade secret.

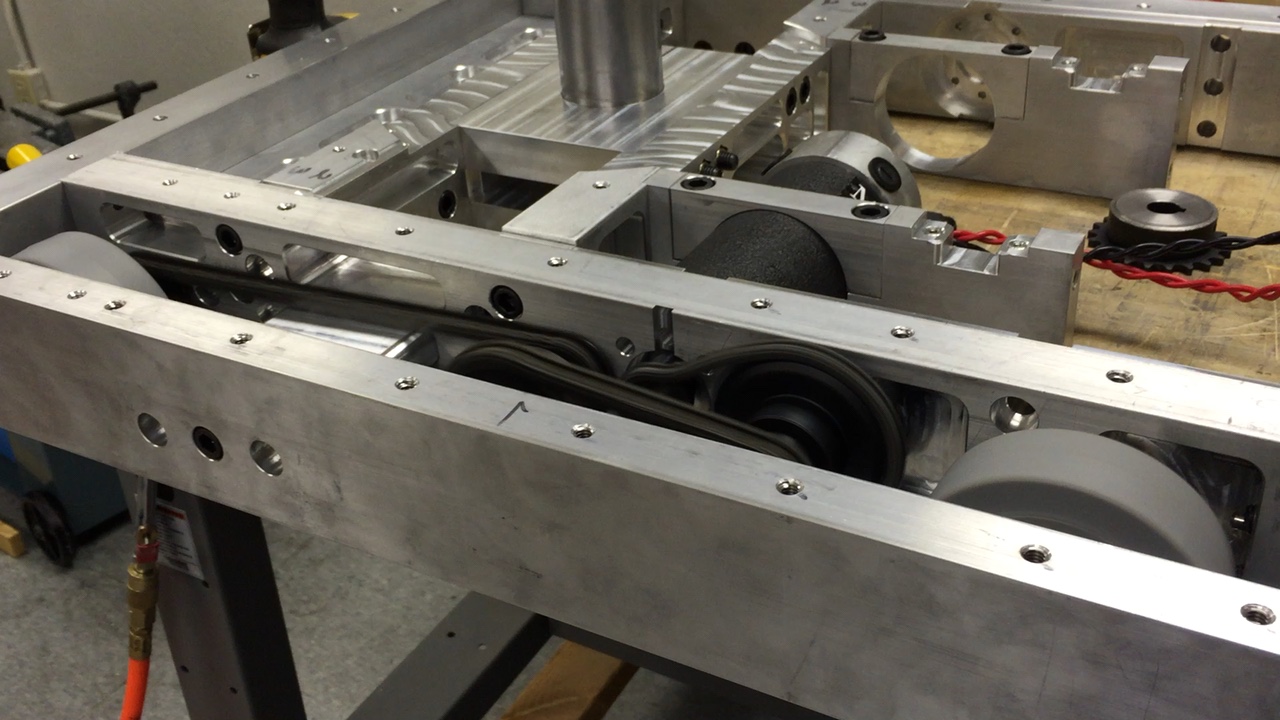

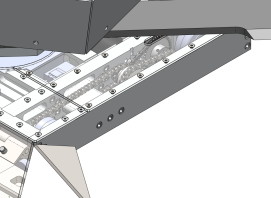

Icewave’s base was carefully designed to be as low-profile as we could get it and still fit in the power and speed it needed to maneuver around the arena. We have just enough armor, an absolute sliver of space around our two powerful Magmotor drive motors, and (honestly) not quite enough space for some elements of our drive train. If you stand really close to your screen, you just might be able to make out the fact that our sprocket-chain drive system actually protrudes through the top armor in two places. Talk about risky business!

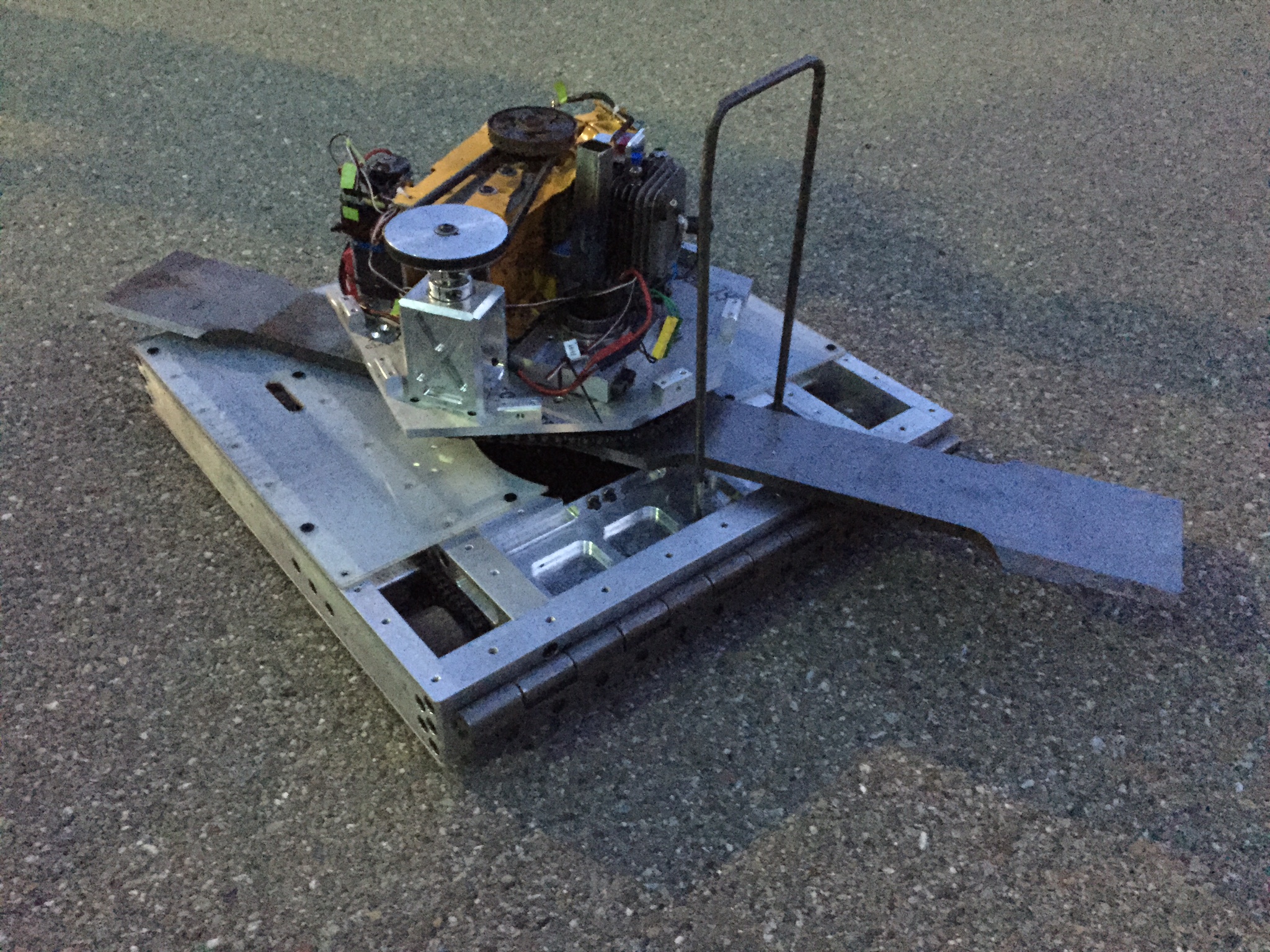

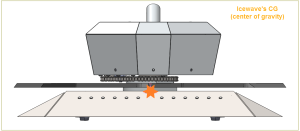

The tradeoff is, of course, stability. In this regard, the new 250lb. weight class has served us well. We were able to weight the drive train with thick enough aluminum to keep the center of gravity* below the blade, making a potentially tragic situation 100% manageable.

Icewave’s Center of Gravity is just under the blade. A fraction of an inch in either direction would make a huge difference, for good or ill.

This is part of why Icewave looks rock-solid after even the biggest hits.

So why not shove the blade up a bit, squeeze the engine in under there and angle it a la Ghost Raptor?

Other than the fact that doing that would make us Ghost Raptor…?

Our tricky paint job may have snuck it past you, but the truth is that Icewave’s 47 pound blade isn’t just a weapon. It’s actually a very important component of the robot’s armor as well as being our enemy-dicing active weapon. Our front wedge, beefy and pretty as it may be, is really more a part of our offensive strategy – a way to shove even the smallest of opponents up into our blade. Our engine armor, while not insignificant itself, is actually not impressive for this weight class. It’s only 1/8″ thick aluminum, which any of the other robots could crunch in half a heartbeat… if they could reach it. It’s the blade and the fact that, no matter which approach you take on us, you are going to hit 300MPH of steel death first that really protects both our drive train and engine.

Crucial to this capability is the fact that the blade is as close to the ground on the sides and back of the robot as it is on the front. Enemy ‘bots can’t sneak in “under the radar” no matter which vector they try for.

Why not an asymmetrical blade?

There were two main reasons we chose to use a symmetrical blade over an asymmetrical one:

- Stability: Given our short build timeframe, we didn’t want to make the robot’s basic spinning stability one of the big problems we would need to iterate and debug. We also wanted to be able to throw all 47 pounds from our weight budget into weapon and weapon strength, and not worry about being forced to put half of it into an offensively and defensively useless counterweight.We felt confident (rightly so) that our engine was still powerful enough to get a lot of inertia behind two spinning tips very quickly.

- As a defensive component, a symmetrical blade “closes the gaps” in our active armor in half the time of an asymmetrical one. Sure, this is no big deal when we’re spinning at full speed and bringing the blade around at about 1800 RPM, but while the blade is recovering from a hit or picking up at the beginning of the fight, we want that defensive edge to come around as quickly as we can get it.

Why does the engine need to be that big, anyway?

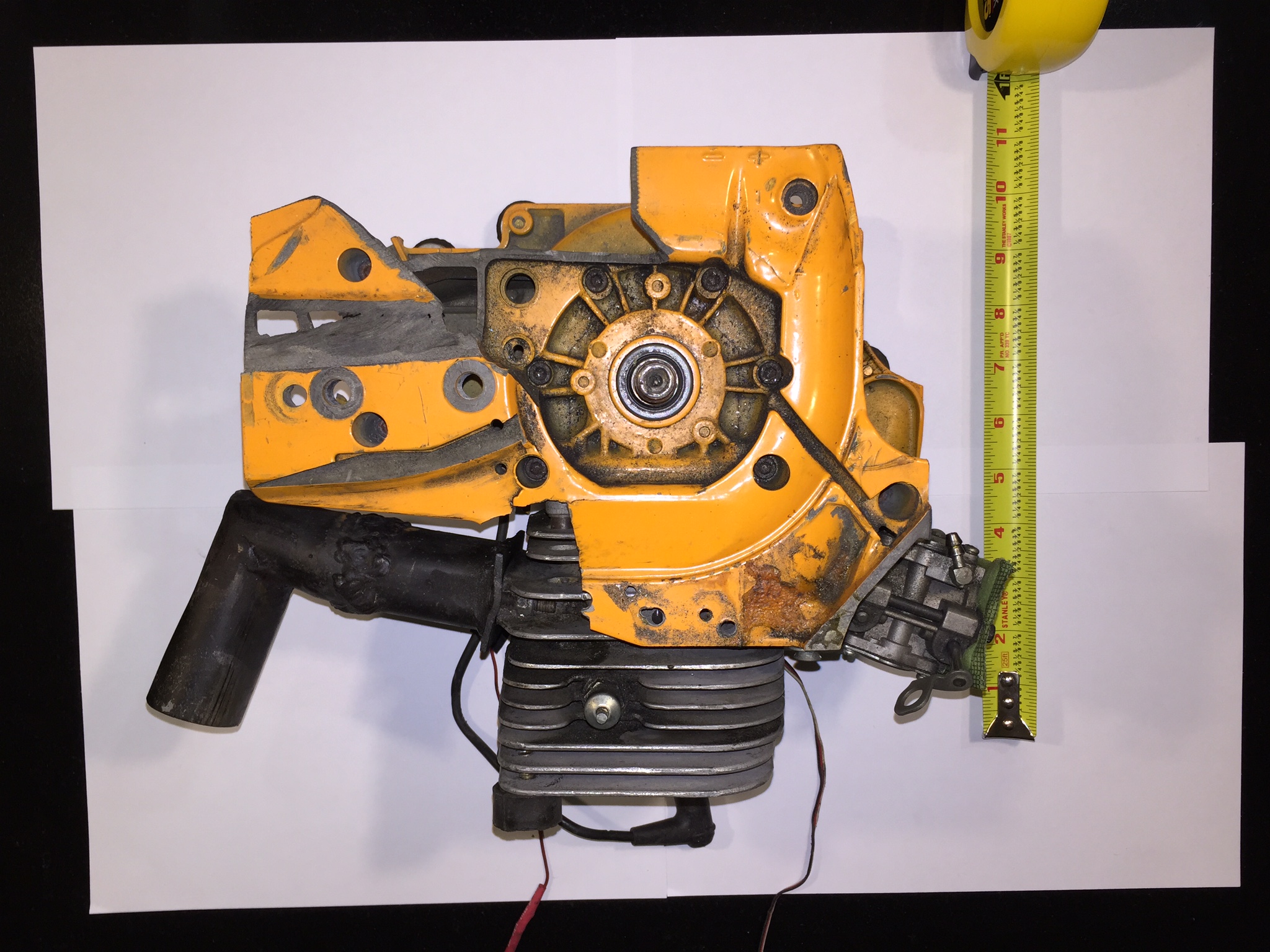

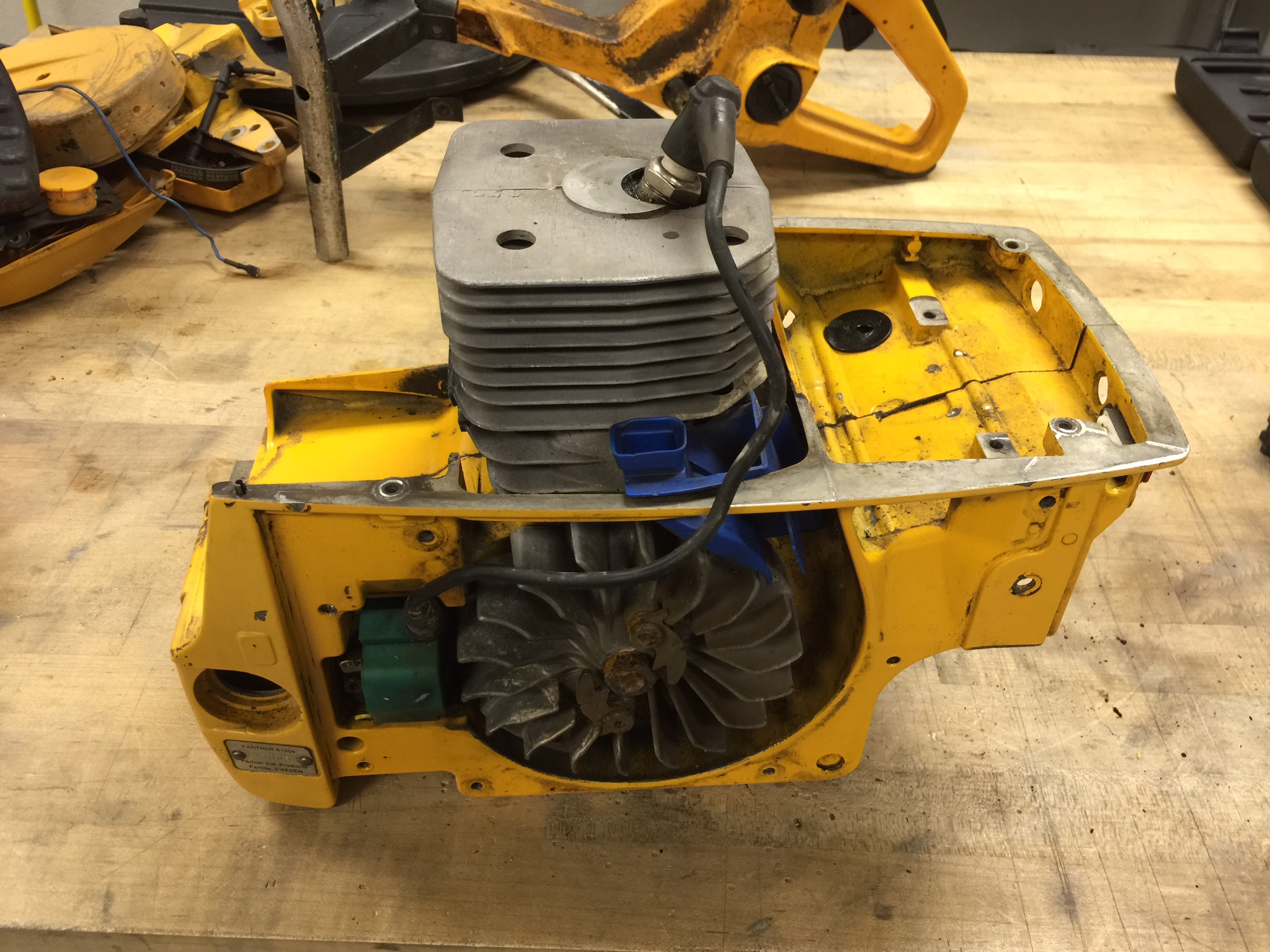

The combustion engine that drives the weapon is pulled from a Partner Husqvarna fire-rescue saw, so we didn’t have any choice about the form factor of that portion of the robot. In any design, death-dealing robot or otherwise, there are always these OTS (off-the-shelf) elements that designers have to just… handle. Work around. Deal with. Design to. Or they design and build their own custom version, which was a task too big for our 5-week build schedule. So we carefully laid out an engine compartment in the only place that made sense: above the blade. This had a few very important effects on the overall design, beyond just weight distribution and balance (not trivial at all).

- A hollow weapon shaft to make a space for wiring to travel from the controls and batteries in the drive train base to the engine starter, choke, and safety switches. The shaft is 2.5″ diameter steel, and although the thickness is classified, let’s just say that it easily handles all the torque we and our opponents can ever throw at it.

- A carefully-geared weapon drive train to transfer the engine’s drive shaft motion to the weapon. This is a combination of a V-belt and a #40 chain.

- A custom-built remote starter assembly that uses a Dewalt motor to drive a custom-designed one-way clutch assembly. When the starter motor is engaged, it can push the engine’s drive shaft until the engine starts, when it spins faster and disengages that clutch interaction.